-

Advantages:

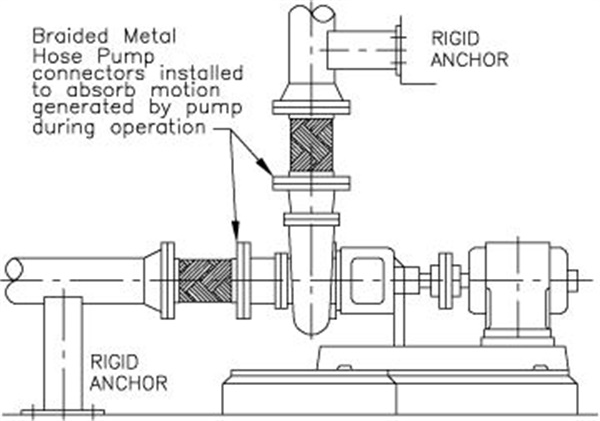

Threaded metal hose pump connector has good flexibility and temperature resistance, pressure resistance, corrosion resistance, fatigue resistance, good flexibility, shock absorption and noise reduction, and strong sealing performance. The metal hose is the main pressure-bearing part of the hose installed in the pressure pipeline, and at the same time, the bellows is sheathed. According to the pressure in the pipeline and the application place, one or more layers of stainless steel wire or steel strip can be selected. Weaving.

-

Application:

It is suitable for medium transportation of steam, water, oil and various industrial gases and medicines.

Threaded metal hoses Product use: metallurgical mining, petrochemical, machinery, coal power.

-

Product performance:

Since the main part of the hose is made of stainless steel, the hose is excellent in temperature resistance and corrosion resistance. The hose used can be selected according to the corrosiveness of the medium through which the pipe is passed, and the corrosion resistance of the hose can be ensured.

1. The metal soft joint is made of stainless steel as a whole and has strong corrosion resistance.

2. The hose body is hydroformed by a thin-walled stainless steel pipe body, which has strong flexibility, flexibility, bending and vibration resistance, and enhanced protection of the woven mesh sleeve to make it have higher pressure bearing capacity.

3. The connections at the ends of the hose can also be made in addition to the threaded and flanged standards for easy connection and use.

4. This product is not only suitable for use with rotary joints, but also widely used for flexible connections in a variety of fluid media delivery.

-

How to choose a threaded metal hose pump connector:

The joints of metal hoses with a diameter of 50 mm or less are mainly threaded when subjected to high working pressure. When the threads are tightened, the inner and outer taper faces on the two joints are tightly fitted to achieve sealing. . The cone angle is generally 60 degrees and is also useful for 74 degrees. The structure is well sealed, but the concentricity of the two mating parts must be ensured during installation.