-

High temperature resistance:

NBR twin sphere rubber expansion joints bring two of the best in the world – oil and high temperature resistance.

The base material of this oil-resistant expansion joint is NBR, which can handle the temperature range from – 40 to + 140 degree C.

NBR rubber joints are used for high temperature applications. It is the perfect choice for oil and fuel, gas, solvent and fat. It also includes mineral oil, vegetable oil and animal oil, oil and gas sol, butane or propane gas. It is not suitable for steam and hot water.

-

Oil resistance:

NBR oil-resistant twin sphere rubber expansion joint provides good oil resistance and hydrocarbons.

The current type of NBR oil-resistant twin sphere rubber expansion joint has moderate aging performance and good wear resistance.

It is suitable for gases, solvents and fats, mineral oils, vegetable oils and animal oils, oil and gas sols, butane or propane gases, etc

-

Wear resistance:

NBR twin sphere rubber joint has wear resistant lining, steel cord reinforcement and CR cap of chloroprene rubber.

The twin sphere rubber expansion joint has good overall oil resistance and wear resistance, flexibility, compressibility and air permeability. NBR wear-resistant rubber expansion joint has moderate aging characteristics.

NBR twin sphere rubber expansion joints with abrasion resistance and oil resistance are suitable for petroleum-based products. Fuel aromatics content is up to 50%, oil-containing anticorrosive additives such as cooling water, lubricating oil and hydraulic oil, seawater.

Temperature ranges from – 20 C to + 90 C, temporarily up to + 100 C.

-

Different environments and different designs:

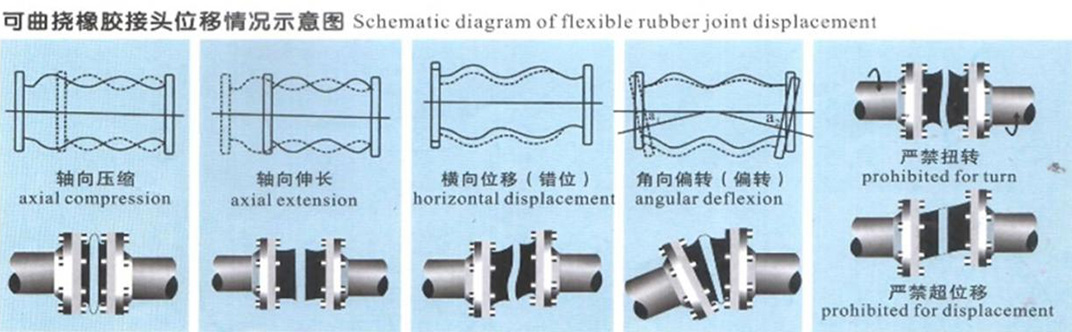

Flexible NBR twin sphere rubber expansion joint is used to absorb thermal expansion and reduce vibration in pipeline system. The rubber sealing surface of NBR rubber joint does not need gasket. NBR expansion joints are not suitable for hot water (100 degree C) and steam. For high vacuum, NBR rubber expansion joint of vacuum device must be used.