-

Production process:

In the process of making the wound rubber soft joint, the inside is not pure rubber, but has a woven mesh. Hand built type rubber expansion jointis made by placing the inner rubber layer blank on the workbench, and the surface of the die is coated with an appropriate amount of the release agent, and then the inner rubber layer tube blank is filled with an appropriate amount of air for the core. After the core is finished, it is finished, inspected, the whole diameter is stored and stored, and the next process is carried out for winding forming.

-

Production considerationsl:

According to the requirements of the production, the branching piece, the mouth shape and the winding stroke of the winding device are determined. Before winding the first wire rubber soft joint, the wire is wound in the direction of the wire through the lead ring, the tension device, the split wire piece, the shaping mouth shape, and then the tape is tightly wound on the lead pipe on the tractor in the winding direction, and the winding machine is started. , the pilot tube is slowly advanced, and the traction speed is adjusted through the governor to make the winding stroke reach the requirement. After the winding stroke is adjusted, the middle film is loaded, and the tube blank with the protective layer is prepared (the surface has been wiped clean with solvent), and the soft joint of the steel wire rubber can be wound. At the beginning of the winding, the speed is gradually increased, and after a certain speed is reached, the middle film is introduced into the winding layer at the same time. When winding, the tension of the steel wire should be uniform, the steel wire should be arranged in order on the tube blank, evenly flattened, and the pressure tube of the traction device should be moderate, and should not be too tight to prevent deformation of the tube blank.

-

Under what circumstances will the hand built type rubber expansion joint be used:

1)The length and hand built type rubber expansion joint are quite different, too short or too long.

2) The small-diameter customer requires the end face to be completely sealed. It should be noted that the buckle-type rubber soft connection is difficult to be wound.

3) The difference between the drilling and the standard is too large, especially if the hole center distance is too large and the mold cannot meet the requirements.

-

Application range:

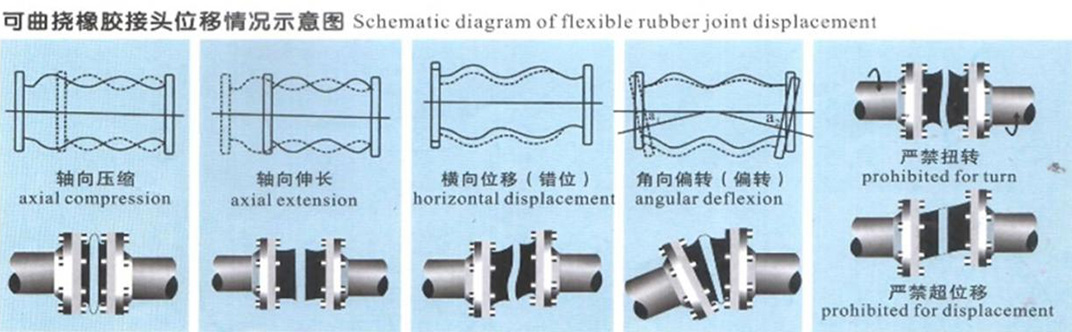

Hand built type rubber expansion joint utilizes the advantages of high elasticity, high gas permeability, medium resistance, weather resistance and radiation resistance of the rubber to reduce vibration and noise, and to compensate for thermal expansion and contraction caused by temperature changes. The spheres are flexible and can be customized to suit your needs. Widely used in a variety of piping systems.