-

Structure:

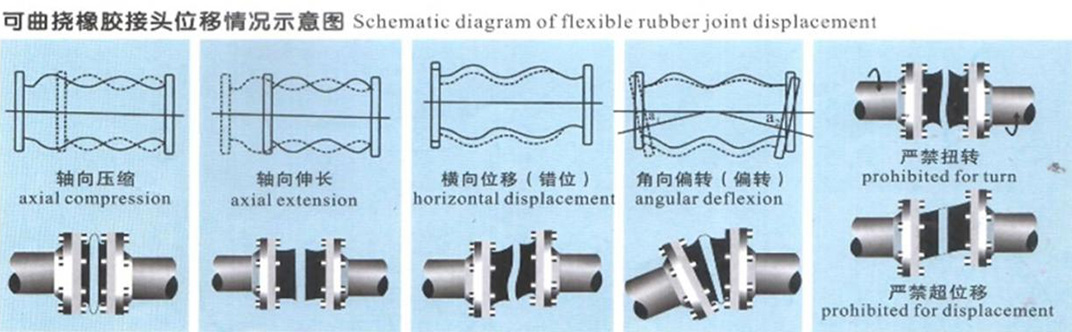

Neoprene rubber expansion joints are flexible “bellows” made by vulcanizing rubber mixtures with reinforced fabrics or steel wires.

In order to increase the compressive resistance of chloroprene rubber expansion joint, the middle wall of bellows is inserted into the reinforcement material of textile or steel wire.

Neoprene rubber expansion joint with rotating galvanized flange, fixed flange or threaded joint with BSPP thread.

-

Use environment:

In addition to oxidizing acid and halogen, chloroprene rubber expansion joint has strong resistance to chemicals and inorganic chemicals. Moderate tolerance to aliphatic hydrocarbons.

This special neoprene expansion joint is suitable for water, swimming pool water, sea water, waste water (weak acid or alkali) or oil, cooling water containing oil additives, lubricants, grease and air, compressed air, etc.

-

Dimensions of chloroprene rubber expansion joints are DN20 to DN3000 mm:

The pressure resistance of standard chloroprene rubber expansion joints is PN 6, PN 10 and PN 16. Voltage resistance depends on the type and size and maximum value. The pressure resistance of expansion joints should be corrected when the working temperature of medium is higher than 50 degree C. The calibration size depends on the type of expansion joint and the material of bellows.

-

Applications:

1) chloroprene rubber expansion joints for water and warm water pressure piping systems for building equipment and general industrial buildings, etc.

2) chloroprene rubber connectors for pumping pipes and turbine pipes in power plants, industrial machinery, general purpose pumps and blowers, etc.

3) Water supply and drainage pipelines for water supply, sewage treatment, sanitary pipeline system, etc.

4) Oil pipes in industrial buildings, shipyards, etc.

5) Loading and unloading routes of ships such as port facilities.