-

Working principle of different diameter rubber joint:

The different name of the different diameter rubber expansion joint is the variable diameter head. As the name implies, the two ports are not the same size. It is mainly used for the piping system with different size difference between the outlet of the pump valve and the outer tube, or the pipeline thickness according to the flow rate of the medium. Changes, changes in the flow of the place will also be used, so that the realization of different sizes of pipes can be connected in a straight line, to achieve pipe diameter reduction pipe fittings.

-

Different diameter rubber soft joint application range:

Reducing rubber soft joints are widely used in various construction, mining, chemical, petroleum and other industries for plumbing and ventilation pipes, water supply and drainage and circulating water pipes, refrigeration pipes, Huagong anti-corrosion pipes, fire fighting, compressor pipes. As well as laboratories, research institutes, ships, ships and other facilities, it is used to protect and control the system pipeline engineering vibration isolation and noise reduction.

-

Construction:

The different-diameter rubber anti-vibration joint (rubber-sized head) is a product consisting of inner layer rubber, nylon cord reinforced, rubber-bending sphere with outer rubber layer and loose flange. During the production process, the inner layer is under high pressure, and the nylon cord fabric and the rubber layer are better combined, and the working pressure is higher and the quality is better than the ordinary flexible rubber joint.

-

Maintenance:

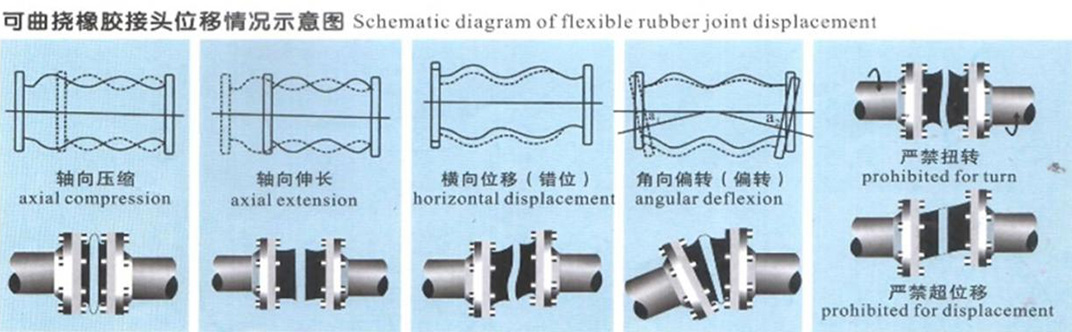

Reducing rubber joints have a certain service life. After a long time, they will age. In terms of preservation, besides being placed in a cool, dry place that is not exposed to sunlight, keep away from strong acids and alkalis. Regularly maintain the working environment of the fittings. Avoid contact with sharp metal instruments to avoid puncture the tube rubber sphere. When using the elastic bracket during installation, the bolts should be tightened diagonally. If the pressure of the rubber joint pipeline is too high, the flanges at both ends should be connected by the limit bolts. The connection of the inlet of the pump unit should generally be installed in parallel to prevent the gas in the pipeline from accumulating at the pump port. It is forbidden to shift, over-limit installation, and away from heat source. It is strictly forbidden to use non-compliant product media joints for installation.