-

Stainless steel metal braided hose features::

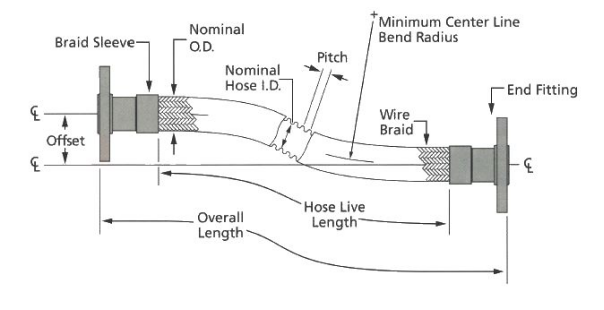

1. Flexible hose between metal hose pitches with small bending radius.

2. The metal hose has good flexibility and is non-blocking or stiff.

3. The metal hose has light weight and good caliber consistency.

4. The metal hose is flexible, repeatable, and flexible.

5, metal hose corrosion resistance, high temperature resistance.

6, metal hose anti-rat bite, good wear resistance.

7. The metal hose is resistant to bending, tensile strength and side pressure resistance.

-

Application:

Stainless steel corrugated hoses In the general industrial field, in addition to pressure and temperature, there are often harsh conditions such as fatigue, corrosion, vibration, pressure, impact, etc., in which case the position of the pipeline is compensated. Mobile is the most appropriate. Widely used for flexible connections in a variety of fluid media delivery. Corrosion resistance, high temperature resistance, low temperature resistance, light weight, small size and good flexibility. Widely used in aviation, aerospace, petroleum, chemical, metallurgy, electric power, paper, wood, textile, construction, medicine, food, tobacco, transportation and other industries.

-

316 stainless steel corrugated braided hose performance introduction:

Since the main parts of the hose are made of austenitic stainless steel, the hose has excellent temperature resistance and corrosion resistance. The hose has a wide operating temperature range of -196-600 degrees. The corrosion resistance of the hose can be ensured by selecting the applicable stainless steel* according to the corrosiveness of the medium through the pipe.

1. The metal hose is made of 1Cr18Ni9Ti stainless steel and has strong corrosion resistance.

2. The hose body is hydroformed by a thin-walled stainless steel pipe body, which has strong flexibility, flexibility, bending and vibration resistance, and enhanced protection of the woven mesh sleeve to make it have higher pressure bearing capacity.

-

Other knowledge:

the installation stress of the pipeline, in the complex pipeline system, often due to the limitations of the space position conditions, resulting in various difficulties in the installation work: the formed pipe can not be loaded; bent over, is coming over, make up the installed pipe , localized cold correction will be avoided. Depending on the pipe diameter and the specific conditions on site, the amount of cold correction ranges from a few millimeters to tens of millimeters, and some hundreds of millimeters. Practice has proved that the larger the amount, the higher the internal stress, and the installation stress of these residues in the pipeline system is undoubtedly a big insult. Because it can be bent at will and the internal stress generated by bending under the rated bending radius is small, it can bring great convenience to the installation work and also guarantee the safe operation of the pipeline system. This is the main reason why some piping systems must use metal hoses.