-

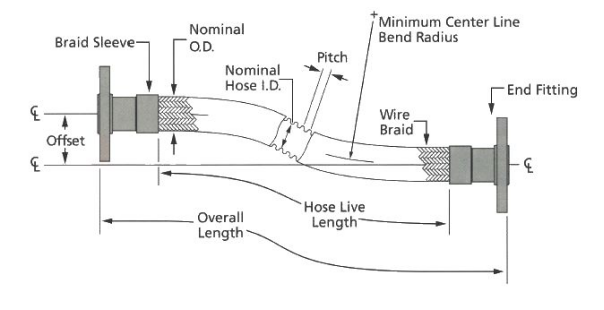

Stainless steel metal braided hose features::

1 Good construction: stainless steel corrugated hose is a thin-walled hose, the overall weight is reduced, greatly reducing the load of construction work and construction time.

2. Corrosion resistance: The main body of the bellows is made of 304 or 316L stainless steel. Both ends are made of stainless steel joints or carbon steel joints, which have good corrosion resistance. Sealing is ensured.

3. High pressure resistance: Considering the actual working pressure of the bellows, the use environment and the use condition, all the parameters have been carefully calculated and tested repeatedly to ensure the pressure safety in the work.

4. Anti-vibration and anti-dislocation: Stainless steel corrugated hose has good flexibility and compensation displacement.

5. Beautiful appearance: the appearance is clear, and the permanent light is as new.

-

Application:

304 stainless steel metal braided hoses range in temperature from 0°F (-18°C) to 850°F (454°C). In rare cases, 316 or 321 can also be used when temperatures up to 1500 °F (816 °C) are required. Most standard constructions are single braided, but can provide double weave for higher pressures or omit weaving for low pressure exhaust or exhaust applications.

-

The origin of metal hose :

Initially, people used suede to form a tubular structure to meet the needs of the production struggle. After a long period of time, by the end of the seventeenth century, the Dutch 10,000 Delgkin brothers made longitudinally stitched canvas hoses, which were widely used in the fire service at the time. Later, with the advent of rubber in the international market and the development of vulcanization processes, hoses and hoses coated with fabrics such as wire or hemp ropes were introduced. However, some high-temperature mediums such as steam and hot air in the project, liquid hydrogen, liquid oxygen, liquid helium-based low-temperature medium; gasoline, kerosene, acid, alkali and other corrosive media, if using a hose to transport, of course not. Especially under high temperature conditions, its safety and reliability is even more difficult to guarantee.

Therefore, people gradually focus on the metal tube, changing the geometry of the metal tube to produce corresponding corrugations on the inner and outer surfaces. In this way, it has the same flexibility as the hose, and at the same time, it has high temperature resistance, low temperature resistance, aging resistance and corrosion resistance. Thus, the metal bellows as the metal hose body is thus produced.

-

The main purpose:

1 transport corrosive chemical or organic solvents. (eg nitrogen water, etc.)

2 transport high temperature gas, hot oil and other high temperature media (such as: hot steam, heat transfer oil, etc.)

3. Transport low temperature or ultra-low temperature media (eg liquid nitrogen)

4. Transport medium such as water and gasoline in a high temperature environment. (eg: water vapor system and hydraulic system in steel making, coking, continuous casting equipment)

5. Pipes that need to absorb or eliminate noise (eg, pump inlet and outlet).